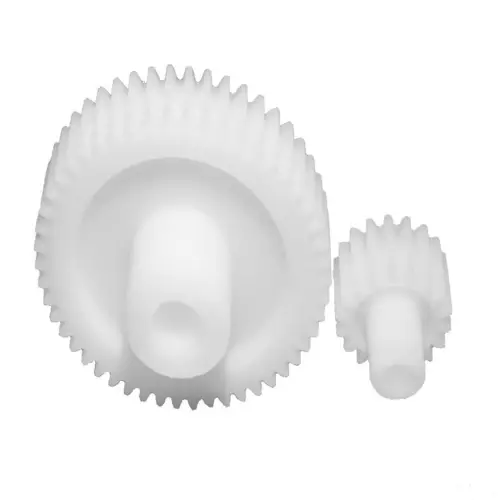

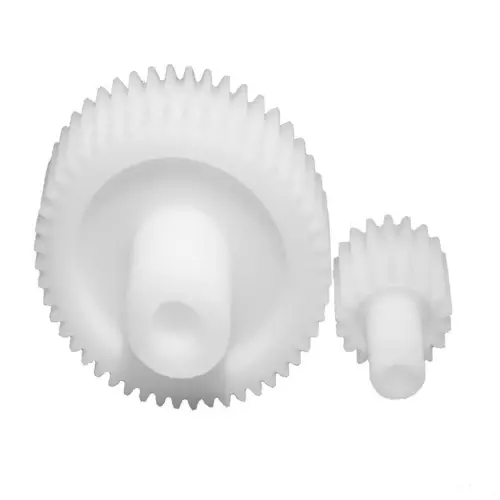

Plastic Spur Gears Innovative Applications

Plastic spur gears have been used in various industries due to their unique characteristics that make them an excellent alternative to metal gears. The innovative applications of plastic spur gears have expanded over the years, making them a popular choice for many applications. In this article, we will explore the different applications of plastic spur gears, their types, advantages, and future development trends.

Plastic Spur Gears Innovative Applications

Plastic spur gears have found their way into many industries, thanks to their unique properties that make them an ideal choice for various applications. Some of the innovative applications of plastic spur gears include:

Home Appliances

Plastic spur gears are commonly used in home appliances such as washing machines, air conditioners, and refrigerators. These gears are lightweight and produce less noise compared to metal gears, making them an ideal choice for home appliances. Additionally, they are more resistant to corrosion and wear and tear, making them durable and long-lasting.

Medical Equipment

The use of plastic spur gears has also extended to the medical industry, where they are used in various medical equipment. These gears are preferred due to their ability to withstand chemical exposure, easy cleaning, and sterilization. They are also lightweight and produce less noise, making them ideal for use in medical equipment.

Automotive Industry

The automotive industry has also adopted the use of plastic spur gears in various applications. These gears are used in windshield wipers, power windows, and many other vehicle components. Plastic spur gears offer many advantages over metal gears, including reduced weight, lower cost, and less noise.

Toys Manufacturing

Plastic spur gears have been used in the manufacture of toys to provide motion to different components. They offer a wide range of design possibilities, allowing for the creation of complex and intricate movements. Additionally, they are lightweight, making them suitable for use in toys.

Office Equipment

Plastic spur gears are commonly used in office equipment such as printers and copiers. These gears produce less noise and vibration, making them ideal for use in office environments. Additionally, they are more resistant to wear and tear and require less maintenance compared to metal gears.

Plastic Spur Gears Informational Relationship

Plastic spur gears have a close relationship with innovative applications. The unique properties of these gears, including their lightweight, corrosion resistance, and low noise production, make them ideal for various applications. Additionally, the design flexibility of plastic spur gears allows for the creation of complex and intricate movements, making them a popular choice for many industries.

Plastic Spur Gears Types and Characteristics

Plastic spur gears come in different types that offer various advantages depending on the application. Some of the common types of plastic spur gears include:

Acetal Plastic Spur Gears

Acetal plastic spur gears are preferred for their low friction characteristics, high wear resistance, and dimensional stability. They are ideal for use in low-load applications that require high accuracy.

Nylon Plastic Spur Gears

Nylon plastic spur gears offer excellent wear resistance, low noise production, and high strength. They are ideal for use in high-stress applications that require high torque.

Polypropylene Plastic Spur Gears

Polypropylene plastic spur gears are preferred for their low cost, good chemical resistance, and good dimensional stability. They are ideal for use in low-load applications that require resistance to chemical exposure.

Plastic Spur Gears Future Development Trends and Opportunities

The future of plastic spur gears looks promising, with many opportunities for growth and development. Some of the trends that are expected to shape the future of plastic spur gears include:

Innovative Design

There will be a focus on developing innovative designs that offer better performance, increased durability, and reduced noise production.

Multifunctional Gears

The development of multifunctional gears that can perform more than one task is expected to increase, with a focus on reducing the number of components required in many applications.

Increased Use of Plastics

With the increasing demand for lightweight and low-cost components, the use of plastics in various applications is expected to increase, creating more opportunities for the use of plastic spur gears.

Choosing the Right Plastic Spur Gear

Choosing the right plastic spur gear requires careful consideration of several factors, including:

Clear Requirements

It is essential to have a clear understanding of the requirements of the application to select the right plastic spur gear.

Material Selection

The selection of the material depends on the application requirements, including environmental exposure, load capacity, and wear resistance.

Design Optimization

The design of the gear should be optimized to ensure that it performs efficiently and effectively in the application.

Supplier and After Sales Service

The choice of supplier and after-sales service is crucial to ensure that the plastic spur gear meets the required standards and performs as expected.

Cost Effectiveness and Quality Control

The cost and quality of the gear should be considered to ensure that it provides value for money and meets the required quality standards.

Plastic Spur Gear Maintenance

Regular maintenance is essential to ensure that plastic spur gears perform efficiently and last longer. Some of the maintenance practices include:

Regular Equipment Inspection

The equipment should be inspected regularly to identify any potential issues that may cause damage to the gears.

Cleaning and Corrosion Prevention

Regular cleaning and corrosion prevention practices are essential to maintain the gears’ performance and durability.

Lubrication and Maintenance

The gears should be lubricated regularly to reduce friction and wear and tear and increase their lifespan.

Replacement of Worn Out Parts

Worn-out parts should be replaced promptly to prevent damage to other components and ensure optimal gear performance.

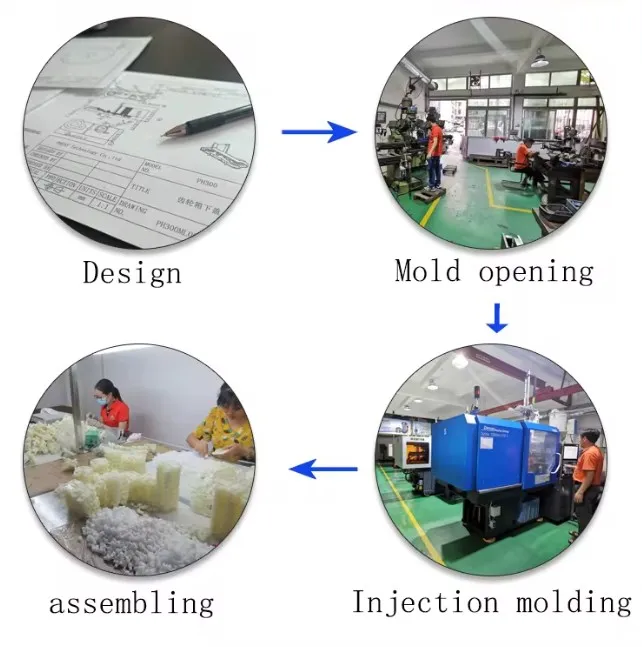

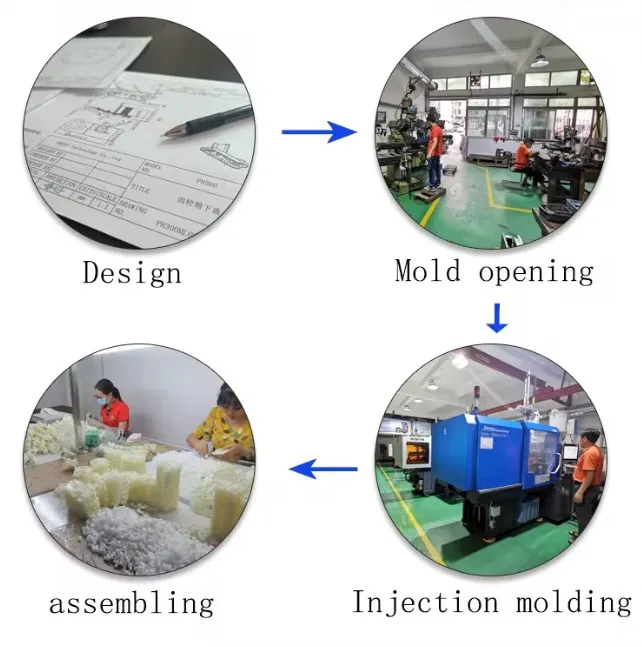

Why Choose Us?

Our company specializes in the production and sale of plastic spur gears. We have been in the industry for many years and have gained extensive experience in the production of high-quality gears. Some of the reasons why you should choose us include:

High-Quality Products

We produce high-quality plastic spur gears that are designed to meet the highest standards of performance and durability. Our products undergo strict quality control checks to ensure that they meet the required standards.

Competitive Prices

We offer competitive prices for our products, making them affordable for various applications.

Excellent Customer Service

We have a team of experienced customer service representatives who are always ready to provide assistance and address any concerns that our customers may have.

Customized Solutions

We provide customized solutions tailored to meet the specific needs of our customers. Our team of experts works closely with our customers to ensure that we deliver products that meet their unique requirements.

Quick Turnaround Time

We have a quick turnaround time, ensuring that our customers receive their orders on time and without any delays.

Q&A

Q: Are plastic spur gears stronger than metal gears?

A: Plastic spur gears are not stronger than metal gears, but they offer many advantages over metal gears, including reduced weight, lower cost, and less noise production.

Q: What are the common types of plastic used in the production of plastic spur gears?

A: The common types of plastic used in the production of plastic spur gears include acetal, nylon, and polypropylene.

Q: What are the maintenance practices required to ensure that plastic spur gears last longer?

A: Some of the maintenance practices required to ensure that plastic spur gears last longer include regular cleaning and corrosion prevention, lubrication, and replacement of worn-out parts.

Q: How do I choose the right plastic spur gear for my application?

A: Choosing the right plastic spur gear requires careful consideration of several factors, including material selection, design optimization, supplier and after-sales service, cost-effectiveness, and quality control.

Q: What are the future development trends for plastic spur gears?

A: The future development trends for plastic spur gears include innovative design, multifunctional gears, and increased use of plastics in various applications.

Author: Dream